Our commitment.

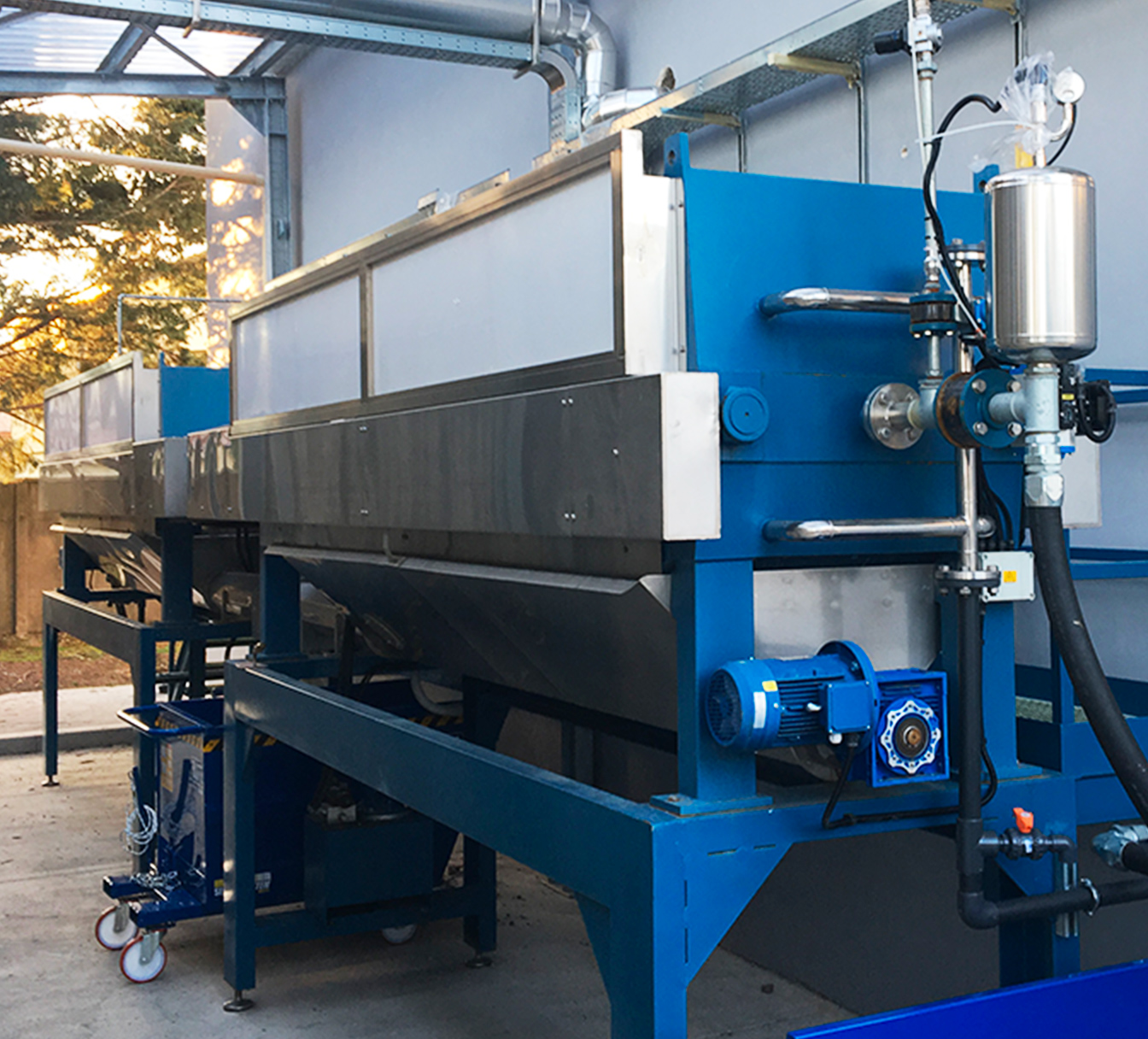

Imprima Group undertook a virtuous path towards a sustainable management of its industrial water.

Textile industry, as is well known, employs a huge volume of water for its productions and has a big impact on water courses pollution.

For this reason, the Group invested on state-of-art purification and recycling systems to improve its water consumption.

Treatment capacity with a maximum discharge rate of 60,000 liters/hour. The outflow complies with the limits of Tab. 3 (discharge to sewer system) of Annex 5, P.terza, Legislative Decree No. 152/2006 of Italian Law.

Treatment capacity of 3,500 liters/hour, with 95% distillation efficiency. The three stages of evaporation together with the vacuum allow great energetic efficiency.

Besides the abatement of pollutants, such as nitrogen, the evaporator allows the recycling of treated and distilled water that can be reused in production processes. The maximum recycling capacity is about 80,000 liters/day.

Treatment capacity up to 15,000 liters/hour, with 95% treatment efficiency.

The outflow undergoes chemical and physical treatments that remove suspended solids and color from the water. The same treated water can be recycled and used for basic industrial processes.

Imprima Group started a water-saving program aimed at reducing water consumption and recycling 10% of industrial water. This is possible thanks to the Group’s depuration systems and its water and energy efficient productive processes.

AND ANNUAL SAVING OF

WATER RECYCLING OF

AND REUSED WATER IN OUR

INDUSTRIAL PROCESSES IN 2023